- 产品介绍

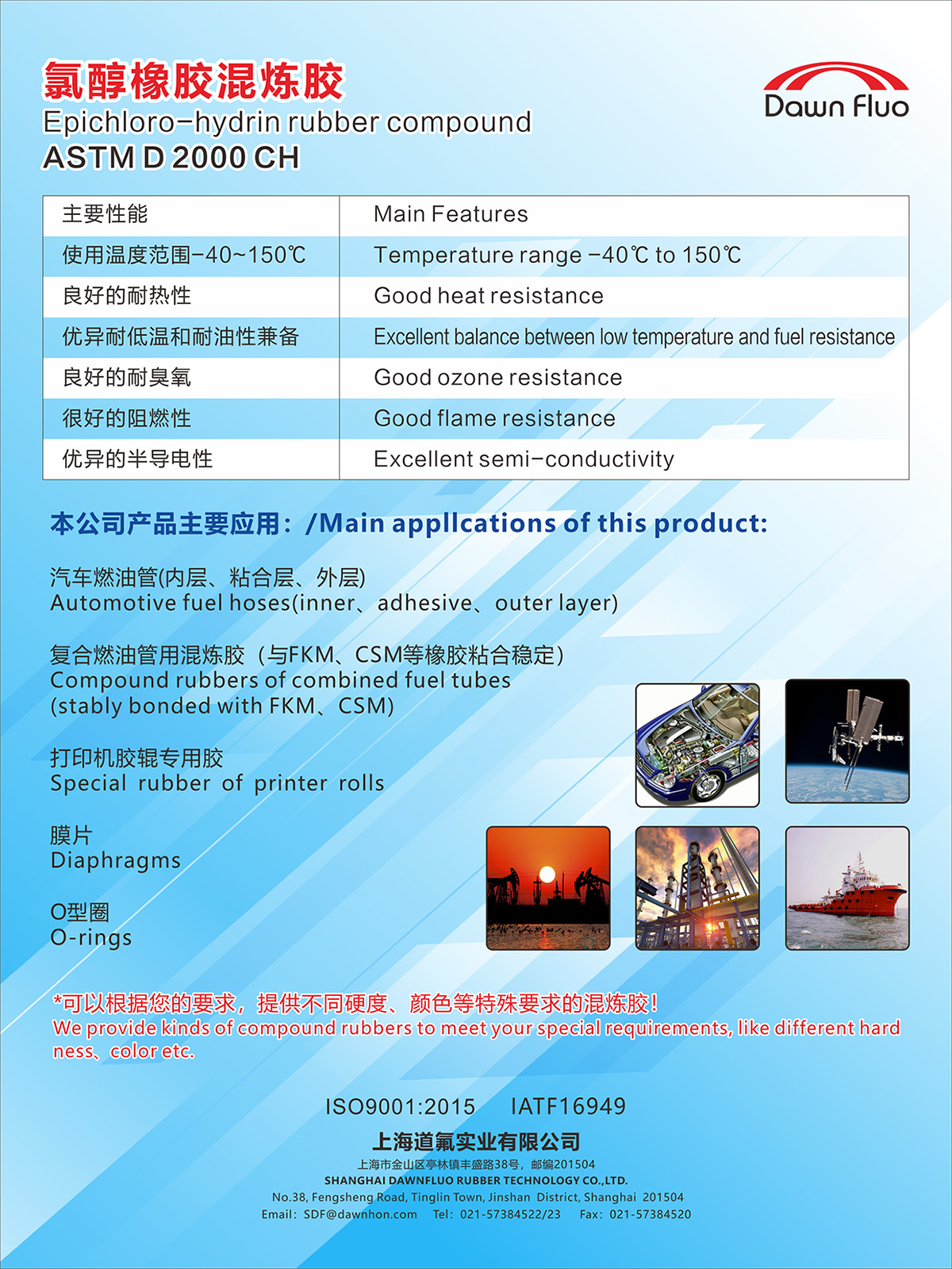

Chlorohydrin rubber (ECO) refers to polyether type rubber with chlorine on the side group. It is a polymer elastomer made by ring opening polymerization of cyclic ethers containing epoxy groups, also known as chloroether rubber. According to its composition, chlorohydrin rubber can be further divided into epichlorohydrin homopolymer chlorohydrin rubber (CO), epichlorohydrin and ethylene oxide binary copolymer chlorohydrin rubber (ECO). The molecular chain of chlorohydrin rubber has good flexibility, thus its cold resistance is good; Due to the presence of chloromethyl polar groups in the molecular chain, chlorohydrin rubber has excellent heat resistance, making it one of the rubbers with the best cold and oil resistance.

Temperature range: -40 ℃~125 ℃

Advantages:

&Middot; Good air tightness

&Middot; Good heat resistance

&Middot; Good ozone resistance

&Middot; Suitable for making seals with Freon refrigerants

&Middot; Suitable for sealing components of rubber hoses and oil well production equipment

&Middot; Suitable for high-pressure piston head components

&Middot; Rubber hoses and shock absorbers (pads, plates, plates) for automobiles and airplanes

Disadvantages:

&Middot; Poor processing performance

Applicable medium:

&Middot; mineral oil

WeChat official account

WeChat official account